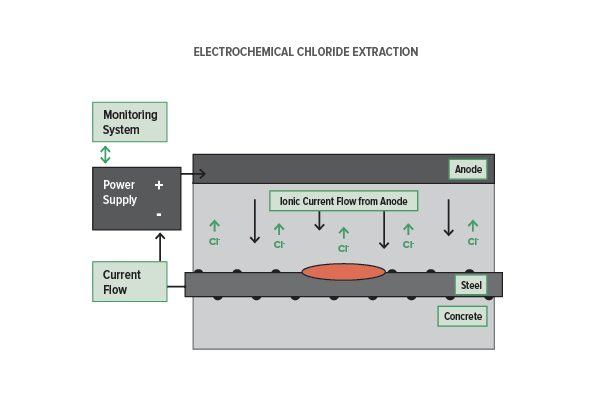

Electrochemical Chloride Extraction (ECE) is also know as electrochemical chloride removal or desalination. The technique uses a temporary anode and passes a high current (about 1A/m2 of steel or concrete surface area) to pull the chlorides away from the steel. A proportion (usually around 50 to 90%) of the chloride can be completely removed from the concrete with very significant removal immediately around the steel and a high level of repassivation of the steel is obtained.

ECE can be used in many of the situations where cathodic protection can be applied. It is at its best where the steel is reasonably closely spaced, the chlorides have not penetrated too much beyond the first layer of reinforcing steel and future chlorides can be excluded. It has been applied to highway structures, car parks and other structures in Europe and North America.

The treatment typically takes six to eight weeks. On completion the anode is removed and there are no ongoing monitoring requirements. If sufficient chloride is removed and further chlorides excluded, then it is a "one off" treatment. Field and laboratory research showed an improvement in concrete properties such as freeze thaw, chloride and carbonation resistance, and water uptake resistance for one set of experiments. The treatment time can be too long for some applications, e.g. bridge decks that cannot be closed for six to eight weeks. The problems with isolated steel, prestressing and ASR mentioned for impressed current cathodic protection are exacerbated for ECE due to the high voltages and current densities. Some concerns with reduction in bond strength have been identified, but these only apply to structures containing smooth reinforcement where the mechanical interlock of ribbed steel is not available. A lithium based electrolyte has been used in trials to mitigate the ASR risk, but results are not yet conclusive on its effectiveness.

What we can do for you

- Review the condition of your structure

- Recommend repair options

- Provide designs and performance specifications

- Provide lists of qualified and experienced contractors

- Provide corrosion monitoring after treatment

More information can be found in the latest edition of my book. Details for ordering are on the home page of the website. There are many other texts covering the mechanisms of corrosion in concrete.

See Corrosion Prevention Association Technical Note No 2: “An introduction to electrochemical rehabilitation techniques”